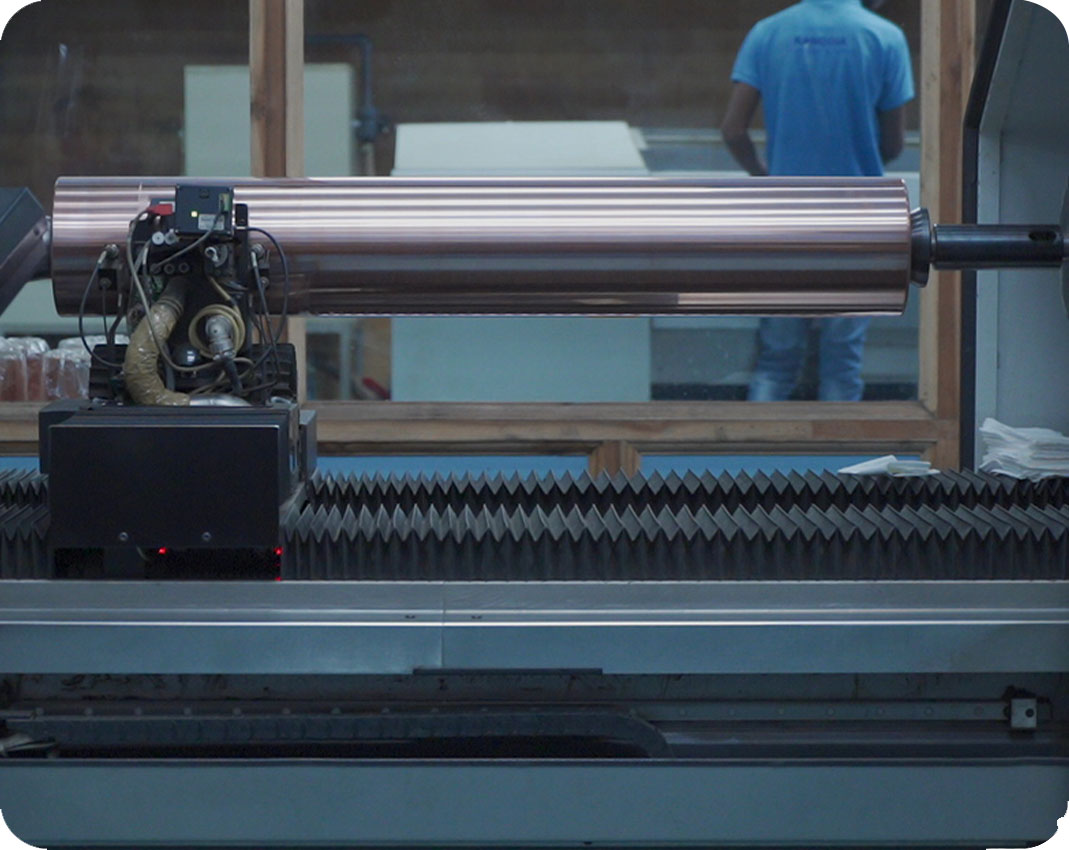

Rotogravure Printing Cylinders

At Kanodia Gravure, we are dedicated to manufacturing high-precision rotogravure cylinders, which are essential for achieving superior printing results across a wide range of production volumes. Our cylinders are meticulously crafted using state-of-the-art technology, ensuring that every aspect of the cylinder meets the highest standards of precision and quality.

Customization to Client Specifications

Each cylinder is custom-engineered to match specific client requirements, including tailored ink compatibility and substrate handling capabilities. This customization ensures optimal ink transfer and superb print clarity, both crucial for maintaining high-quality output in continuous, high-volume production settings.

Technical Features and Innovations

Our rotogravure cylinders feature advanced surface treatments and are constructed from premium materials that enhance durability and performance. The engraving process itself utilises precise electro-mechanical methods or cutting-edge laser engraving, depending on the intricacy of the design and the printing needs. This allows for the creation of highly detailed, deep cells capable of holding more ink and producing richer, more vibrant prints.

Quality Control and Testing

Before deployment, each cylinder undergoes rigorous testing to ensure that it meets all specifications for performance. This includes checks for dimensional accuracy, cell geometry, and the overall quality of the engraved image. Our commitment to quality control guarantees that our cylinders provide consistent results, reducing downtime and waste due to printing errors.

Enhanced Durability and Longevity

To further enhance performance, our cylinders are chrome-plated after engraving, which significantly increases their resistance to wear and corrosion. This chrome layer not only extends the life of the cylinder but also maintains its precision over multiple print runs, ensuring that our clients receive a product that combines longevity with unmatched printing quality.

Through these detailed and client-focused processes, Kanodia Gravure ensures that each rotogravure cylinder produced is not just a component but a pivotal element in our clients’ printing success, driving superior performance and efficiency.

FAQS

We use advanced technologies like electro-mechanical engraving and premium materials, alongside rigorous quality checks, to produce cylinders that deliver consistent ink transfer, sharp detail, and reliable performance for every print run.

Kanodia Gravure

Yes — each cylinder is custom-engineered based on your needs. We adjust cell design, ink compatibility, and substrate support to ensure optimal print quality for your project.

Kanodia Gravure

After engraving, the cylinders are chrome-plated to enhance wear and corrosion resistance. This plating helps them maintain accuracy over multiple runs and prolongs their useful life.

Kanodia Gravure

Every cylinder undergoes rigorous testing including dimensional checks, cell geometry validation, and trial print evaluations to ensure it meets your specifications and performs reliably in production.

Kanodia Gravure

We pride ourselves on fast turnaround. Many cylinders are dispatched within just 3 days to help keep your production schedules on track.